When specifying insulated panels for a project, builders have an array to choose from. But when looking at two of the most popular types— structural insulated panels or insulated metal panels, it is important to understand which is best for the project at hand. While both are insulated and provide most of the wall assembly components, there are big differences in what they are designed to do, as well as where and how they are used.

Here we will discuss the characteristics of structural insulated panels and insulated metal panels, then layout the best use of each.

What are Structural Insulated Panels?

Compared to traditional framing lumber with cavity insulation, structural insulated panels, or SIPs, are a durable and energy-efficient building material most often used in residential and light commercial applications.

Created by laminating a rigid foam insulation core (usually expanded polystyrene) between two structural wood surfaces, SIPs provide thermal control, and a substantial reduction in air leakage vs. traditional stick framed walls with cavity insulation. They also provide significant bracing to the wall assembly in the form of shear load capacity. Because it is missing dedicated moisture management control layers, exterior cladding is necessary to provide bulk water protection as well as the finished appearance, and a backup air/water/vapor control layer is also required. With thicknesses ranging from 4 to 8 inches, SIPs provide approximately R-4 per inch insulation values. SIPs are factory-built units and can be manufactured in varying sizes up to 18 feet in length without additional structural supports. They also contribute significantly to a reduction in jobsite labor vs. stick-built construction.

What are Foamed in Place Insulated Panels?

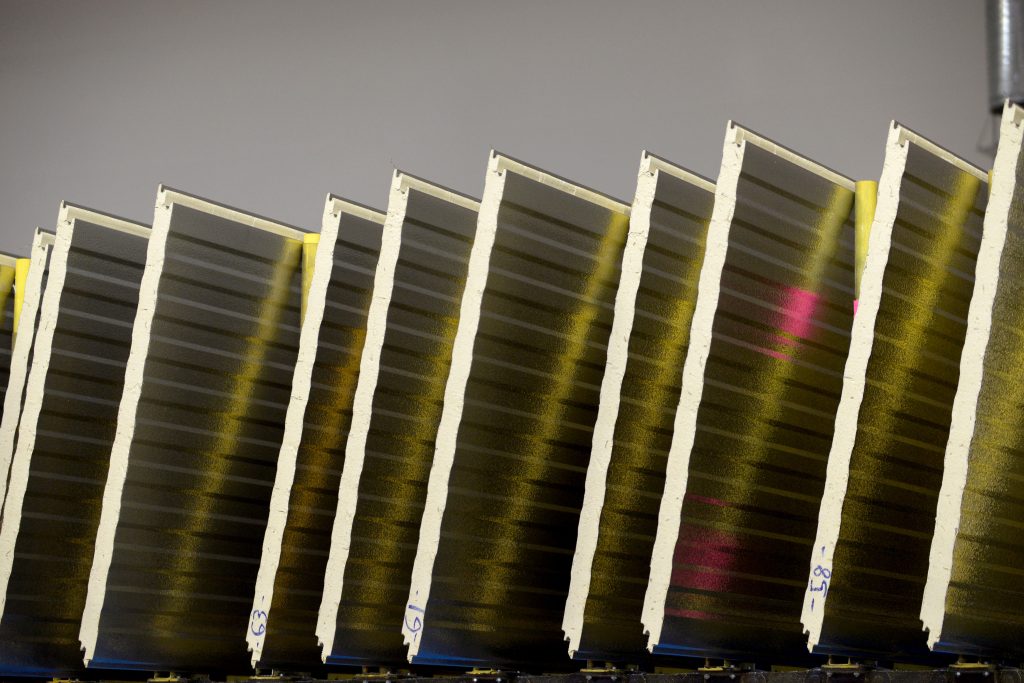

Foamed in place insulated metal panels (IMPs) are the most commonly used type of insulated panels. They are comprised of an outer and inner steel facing with an insulating foam core. Unlike SIPs, IMPs are not used to provide shear resistance to the wall assembly but can resist transverse loads such as wind or snow.

A polyurethane foam core is the most common, and is created by mixing polyol, an organic compound containing multiple hydroxyl groups with one or more chemical isocyanates or di-isocyanates. Because they are highly reactive to each other, the polyol and isocyanates are pumped separately into the spray nozzle where they are mixed. The result is a reaction between the two chemicals that creates a plasticized foam that expands and adheres to the inside surface of the steel facings producing a strong chemical bond between the components. IMPs are mass produced on sophisticated equipment to provide consistent product quality and competitive cost.

IMPs are unique in that this single component provides all four control layers – water, air, vapor and thermal, as well as the exterior and interior finish. Sealants can be factory or field applied within the built-in joint system of the panels, providing extraordinary air, water and vapor control. With thicknesses ranging from 2 to 6 inches and an average R value of well over 7 per inch, IMPs are capable of meeting today’s strict energy codes without the need for supplemental cavity insulation. This greatly simplifies wall system design and construction, minimizes the number of trades required, and expedites the completion of the building envelope. Due to their manufacturing process IMPs are readily available in lengths of up to 50’ or more for vertical installations.

When to Use SIPs versus IMPs

Although there are certainly some commonalities between these two panel systems, each system tends to be used for significantly different applications. SIPs are more commonly used in residential (single and multi-family) and light commercial construction. They are usually associated with wood framed construction but can be incorporated with some forms of steel structures as well.

In comparison, IMPs are predominantly installed on steel framed structures, where the structure itself is braced and provides all the necessary lateral support. IMPs are best described as cladding systems, not structural support systems. Due to their all-in-one functionality, IMPs provide the entire wall/roof system (except for any required wind girts or roof purlins). IMPs are most often specified for larger-scale projects, including commercial, industrial, institutional and high-end architectural applications, including multi-story. Because IMPs come complete with both exterior and interior facings, there is no need to finish out the interior of the wall assembly. The interior panel face may be left exposed, providing a clean, reflective and washable surface. This provides significant cost savings and is an advantage wherever the building interior is subjected to excessive dirt or moisture, or where it must be kept clean to ensure sanitary conditions such as food processing or cold storage facilities.

Both SIPs and IMPs are custom manufactured for the project at-hand, then shipped to the jobsite for installation.

When looking at a project, the main considerations regarding the proper choice of an insulated panel system involves the building structure (wood or steel), structural support framing, end-use, size, budget and aesthetic considerations. SIPs are most commonly used for residential or light commercial projects where wood framed structures are pre-dominant. IMPs are most commonly used with steel framed, larger structures in the commercial, industrial and architectural segments.

If you are still unsure, Metl-Span’s friendly sales staff is standing by to answer any questions you may have. Let us take the confusion out of building for you.

Have Questions About Our Products?

Please fill out the following information and an experienced sales representative will be in contact. We look forward to hearing from you!

View our Privacy Policy