The All-in-One Panel System Offers Protection and Energy Savings in Utah’s Extreme Weather

Brigham City, Utah

Products: ThermalSafe® Fire Resistant Panel, CFR, CF Light Mesa, CF Mesa

Colors: Regal Gray, Slate Gray and Winter White

Architect: Fisher Construction Group

Contractor: Fisher Construction Group

Installer: J&M Steel Solutions

Completion Date: Spring 2024

Nucor Unveils Metl-Span IMP Facility Built with Its Own Insulated Metal Panels

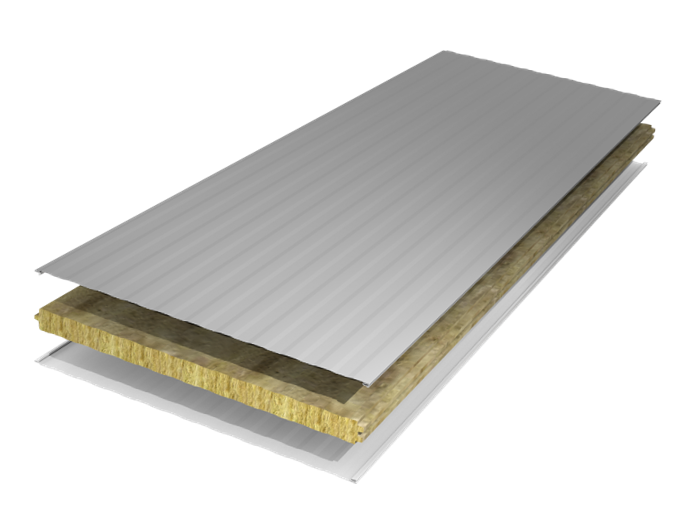

In April 2024, Metl-Span®, a Nucor® company, unveiled a new insulated metal panel (IMP) facility in Brigham City, Utah, which produces insulated metal wall and roof panels for construction projects servicing a variety of market segments. Given that IMPs offer a cost-effective and sustainable all-in-one solution, Metl-Span used its own trusted IMPs to construct the facility’s walls and roofs. This answered the new facility’s need for quality, sustainability, and performance.

The $35 million, 127,000-square-foot plant was constructed in about 13 months despite several interruptions due to heavy snowfalls. Due to the all-in-one nature of IMPs, and the ease of installation, the build team was able to get the building enclosed in a timely manner.

“We’re in the beginning of an IMP revolution,” said Thad Chapman, Vice President and General Manager at Nucor. “IMPs are often the best solution in a construction project, specifically in Utah, a relatively cold area of the country. The Metl-Span metal panel system dramatically reduces our energy costs for operating the building. It also covers air, water, vapor, and thermal all in one panel, which provides the ultimate protection that most buildings need.”

Led by Thomas Studer, Project Manager at Fisher Construction Group, a design/build firm based in Spokane, WA, the project strived to balance speed, efficiency, and quality.

“Flexibility and speed are two huge factors in construction, and the Metl-Span IMPs do both,” he said. “To construct a building of this square footage and dry it within five months is just a testament to how fast IMPs can be installed. My experience with Metl-Span and Nucor was awesome. I would do this job over and over again.”

Metl-Span’s IMPs offer a high level of performance and durability for the state-of-the-art Utah facility, which is subject to extreme temperatures and weather conditions. Since Nucor is a global leader in recycling and sustainable steel production, energy efficiency was paramount when constructing the new facility. Thanks to the IMPs used for its walls and roofs, the facility features advanced energy efficiency and exceptional insulation performance, utilizing a foam system that boasts R-Values of 9 per inch. The panels also allowed the design team to put up walls with greater flexibility than coordinating concrete and tilt-up walls with engineers.

“The benefit of Metl-Span panels is that it’s an entire system,” said Studer, “It’s lower cost and faster than a system that is not all-in-one.”

Regal gray, slate gray, and white panels were selected to achieve visual contrast throughout the building. A combination of wall and roof panels were used to accommodate different needs and sizes. The team also selected ThermalSafe® Fire Resistant Panels to maximize fire resistance.

Marvin Goeckeritz, General Manager at J&M Steel Solutions, Inc., led the installation of the IMPs and echoed that it was the most efficient choice for the job. “The panels are large compared to standard single-skin metal panels but easy to maneuver with the correct equipment and panel-picking devices,” he said. “What’s great about an insulated metal panel system is the crew does not need to install the insulation separately as the panel system is an all-in-one product.”

This project included vertical and horizontal wall panel installation positions. For the roof, Goeckeritz said the crew installed 124,400 square feet of CFR insulated standing seam roof panels. The interior partition walls and office walls utilized 9,500 square feet of TS ThermalSafe Fire-Resistant Ultra-Light Mesa panels. The exterior walls used 66,800 square feet of CF Mesa and Light Mesa panels.

The installation process for J&M Steel included prepping the panels by the ground crew, who installed butyl at the panel laps and connected the panel picker to each panel to fly them to their final location.

“At the panel installation point, you have crew members where each panel ends and at the midpoint of the panel or several locations along the panel depending on the length,” said Goeckeritz. “When installing wall panels, the crew is working out of man lifts; when installing the roof panels, the crew is tied off and working on the roof.”

He added, “The insulated panels provide a great weather-tight seal and awesome thermal insulation values. They install quickly and provide the builder with a product that can be installed in variable weather conditions.”

The cold and snowy Utah winter posed some challenges as the facility was being built. It was a record year for snowfall, which caused some delays and required creative solutions. For example, when pouring concrete in the winter, the crew had to unthaw the ground beforehand to prevent the concrete from freezing as it cured. The team brought in heaters, closely tracked supplies, and made the most of the conditions to keep the project on track.

However, the panels themselves were unaffected by severe weather. “The great benefit of using the insulated metal panel system during these weather conditions is the installer doesn’t have to worry about insulation being blown away or ruined from the amount of moisture coming down while you are working,” said Goeckeritz. “A typical pre-engineered building uses batt insulation and a single skin metal panel to cover it. In adverse weather conditions, you must stop installing roof panels due to winds blowing the batt insulation away or the insulation taking on too much moisture. There’s no need to worry about this with an insulated metal panel system.”

In mid-April 2024, Metl-Span marked this significant milestone and the facility’s completion with a grand opening celebration and ribbon cutting, with over 100 attendees. Moises Castro, Operations Manager at Nucor, said there are several enhancements to the new plant.

“What makes this facility exciting is that we have state-of-the-art equipment and one of the best teams that Nucor can have,” said Castro. “This production line is capable of quick changeovers per design, and we also have the latest technology for our testing labs.”

Studer called out another unique aspect of the plant’s manufacturing capabilities that come into play for the design of a new cold-storage facility he’s working on in California. With the plant’s ability to produce panels up to 75 ft. long, it eliminates or reduces the need for stack joints in certain cases, which saves on time and costs.

Now in full operation, this plant stands as a testament to IMPs as a solution to energy performance in any climate and as an all-in-one installation to meet tight construction timelines. According to Thad Chapman, “The new facility marks a significant expansion for Metl-Span that allows the company to better reach and serve our customers in the western United States and Canada. This state-of-the-art facility will greatly enhance our ability to deliver the unparalleled level of service that our customers have come to expect.”

Metl-Span is a Nucor® company. (NYSE: NUE ); delivering high-quality, durable and energy-efficient insulated metal panels designed for unparalleled performance to stand the test of time.

Have Questions About Our Products?

Please fill out the following information and an experienced sales representative will be in contact. We look forward to hearing from you!

View our Privacy Policy